-

Mass Production Core Strength[1] Design and development of custom components for structural and electronic functions

[2] Product and production process innovation program research and development

[3] Automated production line design and application

[4] APQP project management ability

[5] Six Sigma Black Belt teams analyze and solve problems -

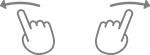

End-to-End Solutions【1】 Develop Steam Output Based on Customer Needs

① Customize steam output solutions tailored to the customer’s application scenarios and performance requirements.

② Aim to achieve precise control and efficient output of steam volume to meet practical usage demands.

【2】 Core Module Design for Steam System

① Push Mechanism Design: Ensure stability and airtightness of the water tank’s push in/out supply to enhance water supply reliability.

② Heater Design: Optimize heating efficiency and thermal response time to balance energy consumption and performance.

【3】 System Control Development: Develop an integrated control system for precise regulation of steam volume, temperature, and operational timing.

① System Performance Evaluation and Validation

② Conduct system-level performance testing based on customer-provided technical requirements and application scenarios.

③ Generate evaluation reports to verify the design’s reliability, safety, and applicability, ensuring the final solution meets customer expectations.【1】 Develop Steam Output Based on Customer Needs

① Customize steam output solutions tailored to the customer’s application scenarios and performance requirements.

② Aim to achieve precise control and efficient output of steam volume to meet practical usage demands.

【2】 Core Module Design for Steam System

① Push Mechanism Design: Ensure stability and airtightness of the water tank’s push in/out supply to enhance water supply reliability.

② Heater Design: Optimize heating efficiency and thermal response time to balance energy consumption and performance.

【3】 System Control Development: Develop an integrated control system for precise regulation of steam volume, temperature, and operational timing.

① System Performance Evaluation and Validation

② Conduct system-level performance testing based on customer-provided technical requirements and application scenarios.

③ Generate evaluation reports to verify the design’s reliability, safety, and applicability, ensuring the final solution meets customer expectations.【1】 Provide Solutions for Pulsator and Drum Washing Systems for Various Washing Scenarios

① Customize and optimize designs based on the customer’s product structure and functional requirements.

② Balance cleaning efficiency, energy savings, and cost control.

【2】 Ozone Disinfection Technology Solution

① Utilize ozone generation and control technology to achieve efficient disinfection of clothes or chambers.

② Offer eco-friendly benefits with no residue.

③ Incorporate simulation analysis and patented designs to enhance the solution’s originality and feasibility.

【3】 Specialized Valve Design

① Develop valves with specialized structures tailored to different system pressure, flow, and sealing requirements.

② Ensure precise integration with the overall system to improve reliability and service life.【1】 Provide Solutions for Pulsator and Drum Washing Systems for Various Washing Scenarios

① Customize and optimize designs based on the customer’s product structure and functional requirements.

② Balance cleaning efficiency, energy savings, and cost control.

【2】 Ozone Disinfection Technology Solution

① Utilize ozone generation and control technology to achieve efficient disinfection of clothes or chambers.

② Offer eco-friendly benefits with no residue.

③ Incorporate simulation analysis and patented designs to enhance the solution’s originality and feasibility.

【3】 Specialized Valve Design

① Develop valves with specialized structures tailored to different system pressure, flow, and sealing requirements.

② Ensure precise integration with the overall system to improve reliability and service life. -

Independent Innovation[1] Peristaltic pump series products

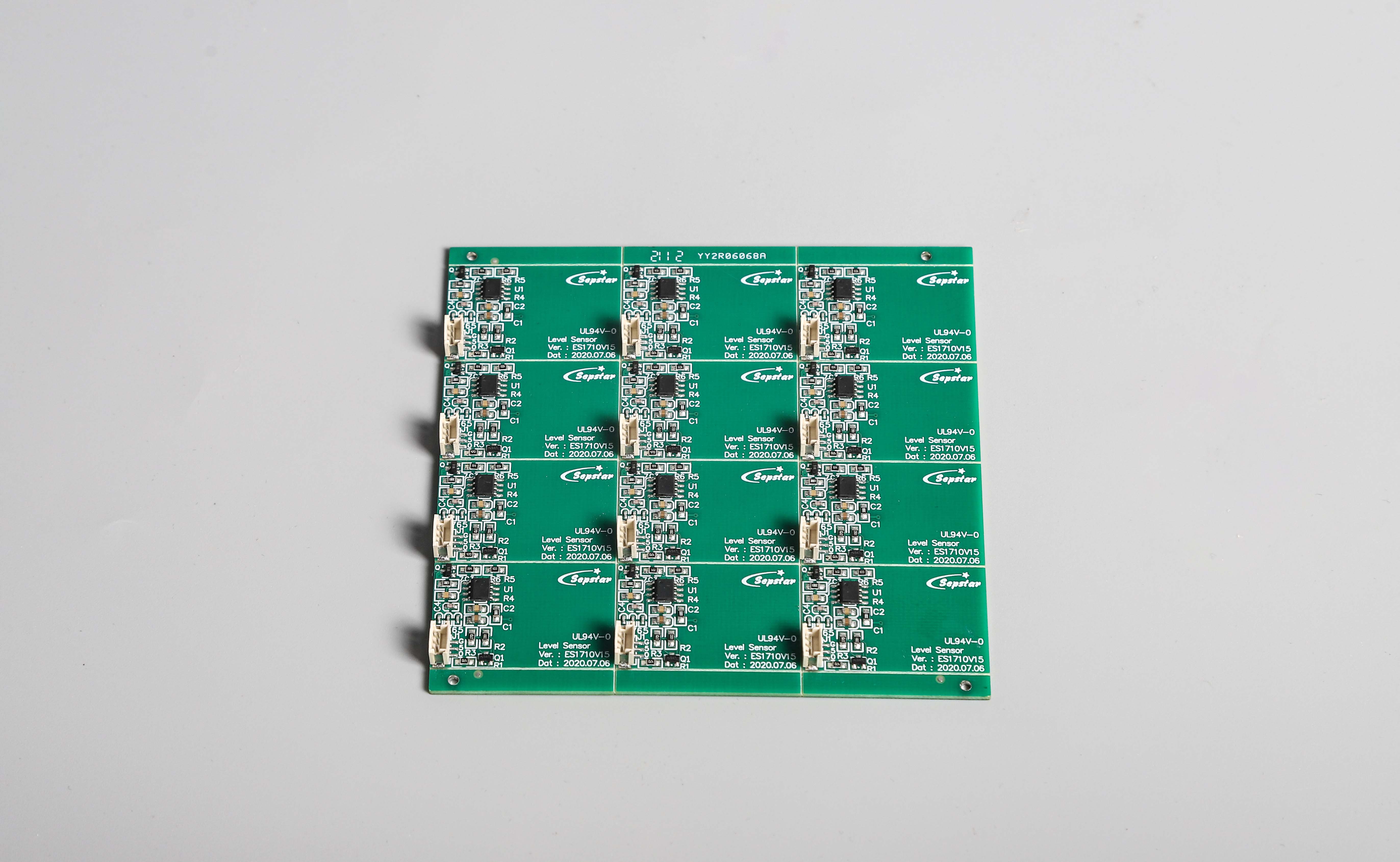

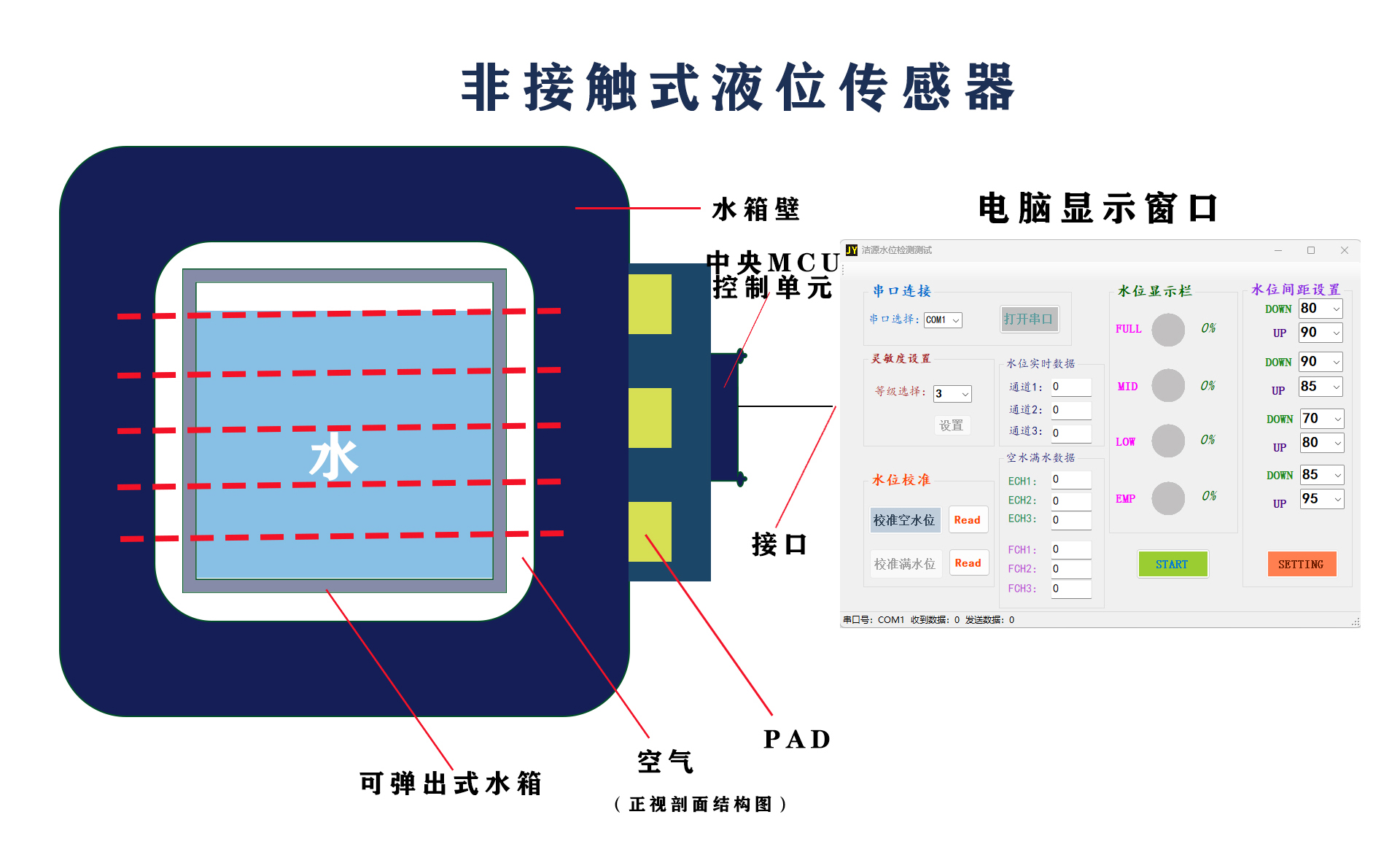

[2] Water level sensor and special water level display solution

[3] IMC/IME series products

[4]Other applications of steam system (application design of washing machine and dishwasher)

Participate in customer new product development

-

Sepstar Zhuhai x Electrolux: High-Sensitivity, High-Precision Non-Contact Electronic Liquid Level Sensor

Sepstar Zhuhai x Electrolux: High-Sensitivity, High-Precision Non-Contact Electronic Liquid Level Sensor -

Sepstar Zhuhai x Electrolux: Pop-Out Steam Water Tank

Sepstar Zhuhai x Electrolux: Pop-Out Steam Water Tank

Core technology

Home

Home

Product

Product

News

News

Contact

Contact