Non-Contact Liquid Level Sensors

- Introduction

Jieyuan’s non-contact liquid level sensors are widely applied in household appliances such as ovens, water tanks, coffee machines, soy milk makers, and syrup dispensers. Beyond home appliances, these sensors are also integrated into intelligent equipment across industrial, agricultural, and environmental applicationswhere liquid monitoring is required.

With rapid advances in technology, liquid level sensing has evolved significantly—from traditional mechanical methods such as float levers, reed switches, and electromagnetic sensors to modern capacitive detection, greatly improving both performance and usability.

Traditional sensors often require direct immersion of probes in liquid or the use of floats that actuate reed switches. These approaches add structural complexity, increase costs, and suffer from reduced durability.

Jieyuan’s non-contact technology resolves these issues with advantages including non-intrusive detection, ease of integration, low cost, and long service life. The technology leverages:

- Dedicated capacitive hardware circuits with built-in MCU

- AI-driven algorithms

- User-friendly visualization interfaces

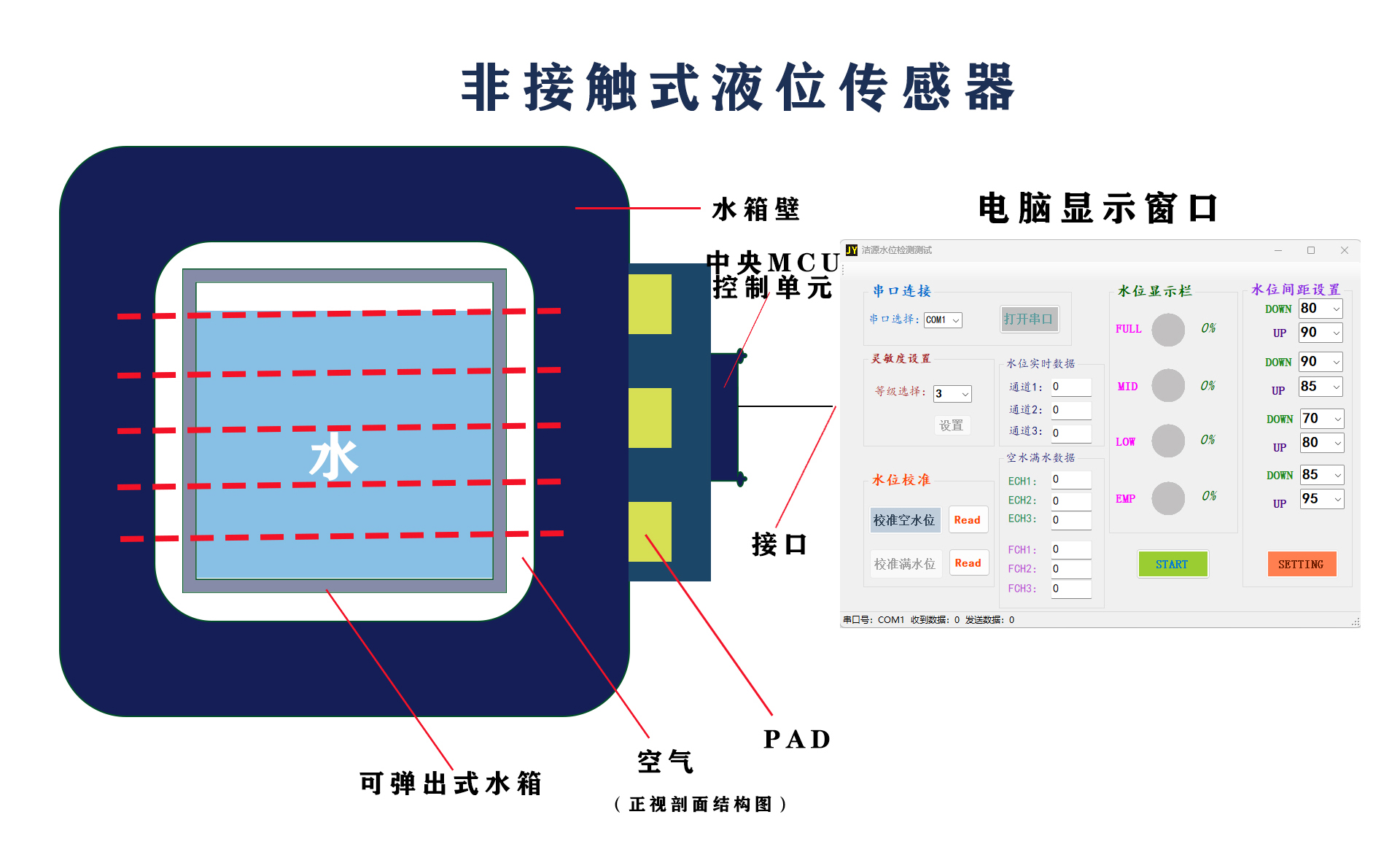

No direct liquid contact is required. The PCB remains isolated, capable of functioning through 4–8 mm insulating materials and 1–3 mm air gaps, while still achieving accurate non-contact water level detection.

- Basic Usage Instructions

- Affix the sensor board closely to the container wall.

- Connect a 5V power source at the power interface; the POWER LED will remain lit to indicate normal operation.

- Connect the board to a computer via USB-to-TTL serial interface and use the dedicated software for real-time monitoring and calibration.

- Detection Principles

- Changes in the dielectric medium between the PCB and container cause micro-capacitance variations.

- The sensor board’s high detection sensitivity allows identification of small capacitance changes due to liquid level fluctuations.

- Supports 2–3 mm non-contact sensing distance(air gap), providing tolerance for different installation setups.

- Capable of compensating for changes caused by scale buildup(via recalibration).

- Compatible with container wall thicknesses up to 6 mm.

- Software Interface

- Adjustable sensitivity levels, defining how much liquid coverage over the copper pad qualifies as “liquid detected.”

- Customizable percentage thresholds for each water level point (for both rising and falling liquid levels).

- Real-time monitoring of multiple water levels, transmitting integer data and proportional values to the host interface.

- Initial calibration (empty and full levels) ensures accurate measurement during first use.

Software interface

Product Portfolio

- Automotive:Intelligent surfaces, lighting systems, car audio

- Home Appliances:Refrigerators, washing machines, ovens, dishwashers, small appliances

- Consumer Electronics:Oral irrigators, liquid level sensors, peristaltic pumps

- Full Product Range:Peristaltic pumps, dishwasher control panels, oven water tanks, washing machine control panels, ice crushers, refrigerator handles, automotive audio systems, tail lamps, micro peristaltic pumps, liquid level sensor PCBs, and liquid level display modules.

Home

Home

Product

Product

News

News

Contact

Contact