-

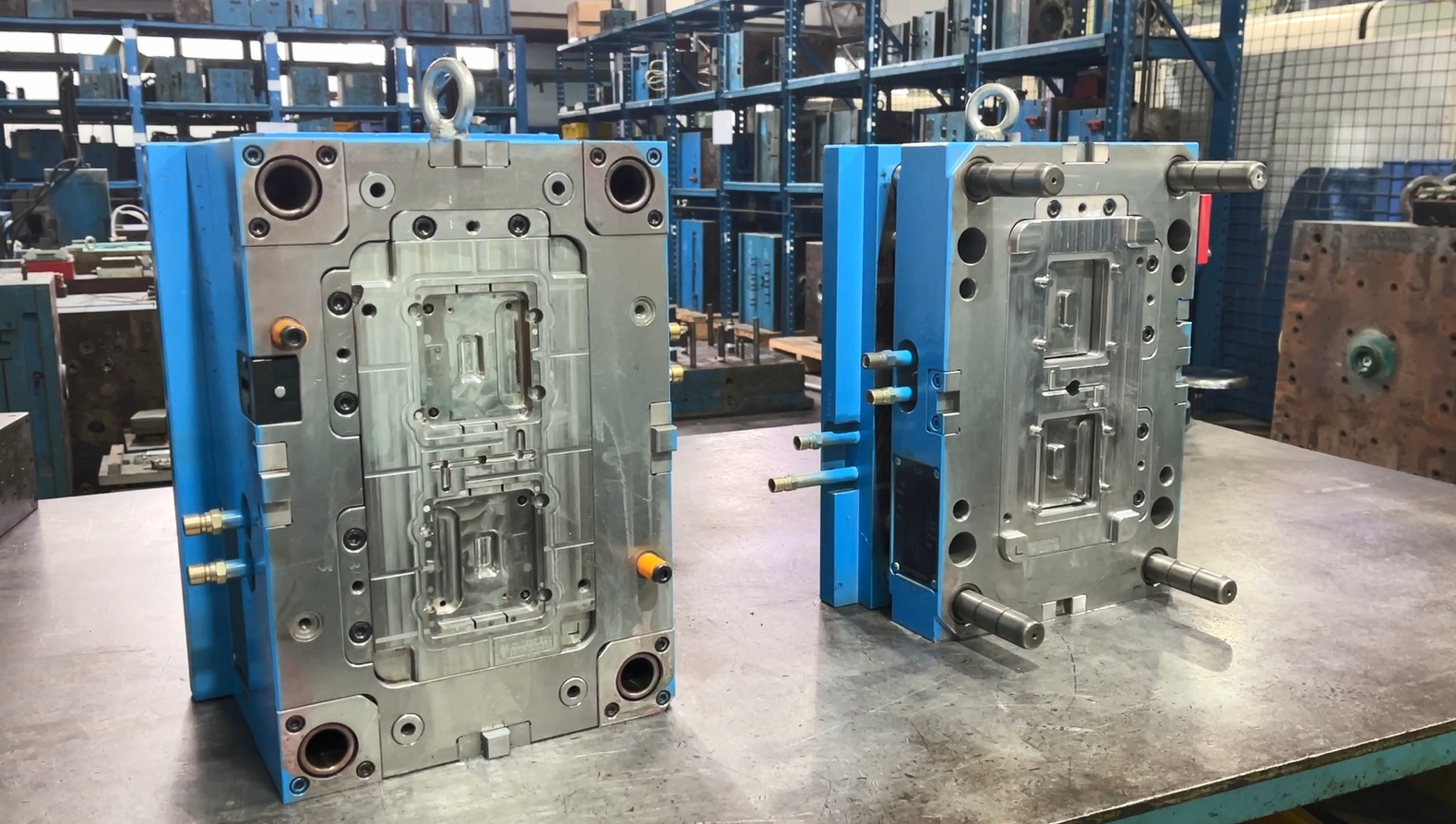

Mold design and manufacturing【1】Precision mold design

【2】 Mold maintenance【1】Precision mold design

【2】 Mold maintenance -

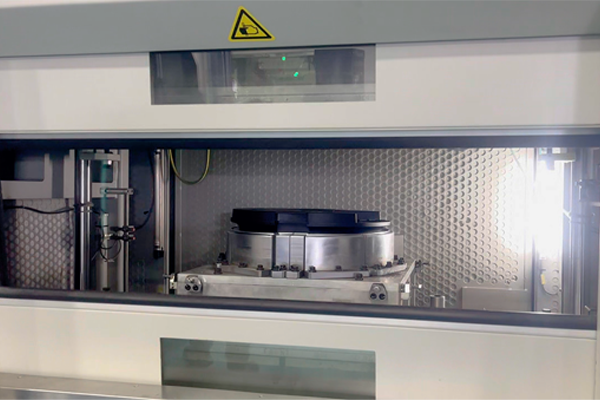

Injection molding and assembly1. Precision Parts Injection Molding (50T–800T), integrated with six-axis robotic arms

2. Two-Color Injection Molding

3. IML / IMC / IME Injection Molding

4. One-Stop Solution for Printing and In-Mold Decoration (IMD)

5. Microcellular Foaming Injection Molding

6. Thermoset Material Injection Molding

7. Automated Production Line Design and Implementation

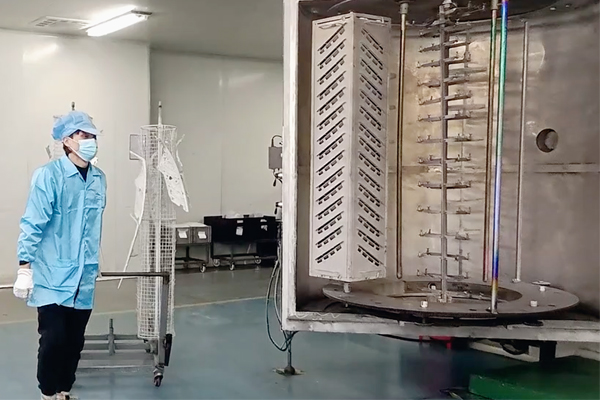

Post-Processing Excellence

Home

Home

Product

Product

News

News

Contact

Contact