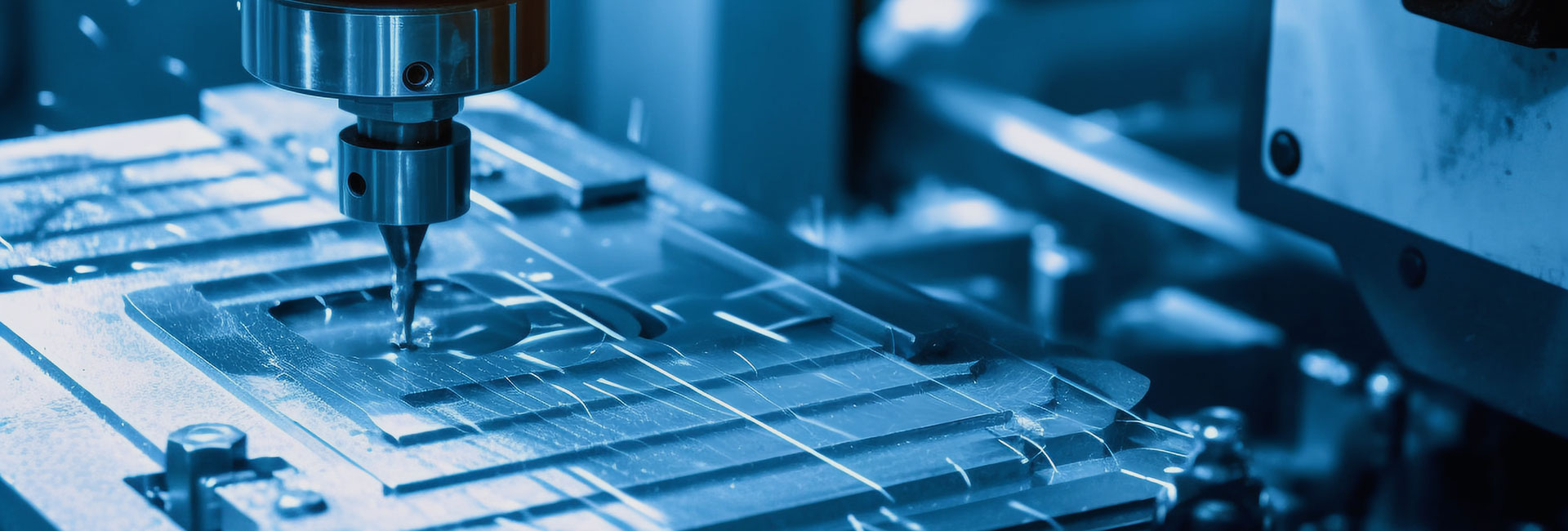

IME is an advanced technology that integrates traditional In-Mold Decoration (IMD) processes with printed electronics. It typically involves printing high-performance electronic pastes onto IMD films, embedding touch controls and other electronic components into a single part to create intelligent surfaces. Its key advantage is enabling thinner, lightweight product designs. IME delivers both decorative aesthetics and functional electronics, making it a critical enabling technology for smart surfaces in automotive, home appliances, and medical devices.

Process Description

IME (In-Mold Electronics) combines IMD (In-Mold Decoration) with flexible printed circuit technology. The process integrates printed circuitry, SMT component placement (LEDs, resistors, capacitors, sensors, IC chips, etc.), high-pressure forming, and injection molding into a unified intelligent surface solution. The resulting IME control interfaces can reliably deliver all intended functions while achieving up to 60% weight reduction compared to traditional mechanical switches, supporting industry goals for lightweighting. This technology has broad applications across automotive, home appliances, consumer electronics, and medical devices.

Technical Challenges of IME

IME offers many advantages, including compactness, space efficiency, durability, faster time-to-market, and high throughput capacity. However, it also presents challenges such as shape limitations, yield issues, immature software ecosystems, environmental stability concerns, and post-processing difficulties.

- Since IME requires circuits and electronic components to be printed and bonded onto thin films, thermal tolerance is a key issue. Most films withstand only up to 140°C, while soldering of components typically requires temperatures above 170°C.

- Conductive adhesives used for bonding often result in weaker joints and lower production efficiency.

- After SMT mounting on film, subsequent high-pressure thermoforming and injection molding may cause delamination, bubbling, or ink smearing.

Home

Home

Product

Product

News

News

Contact

Contact